22nd Mar 2023

Construction equipment breakdowns can be a major inconvenience for the crew. Fortunately, there are ways to reduce the frequency of breakdowns and save money on repair bills.

One of the essential elements of preventive maintenance is an effective program. This requires a comprehensive knowledge of equipment capabilities and limitations as well as instruction on safe handling techniques.

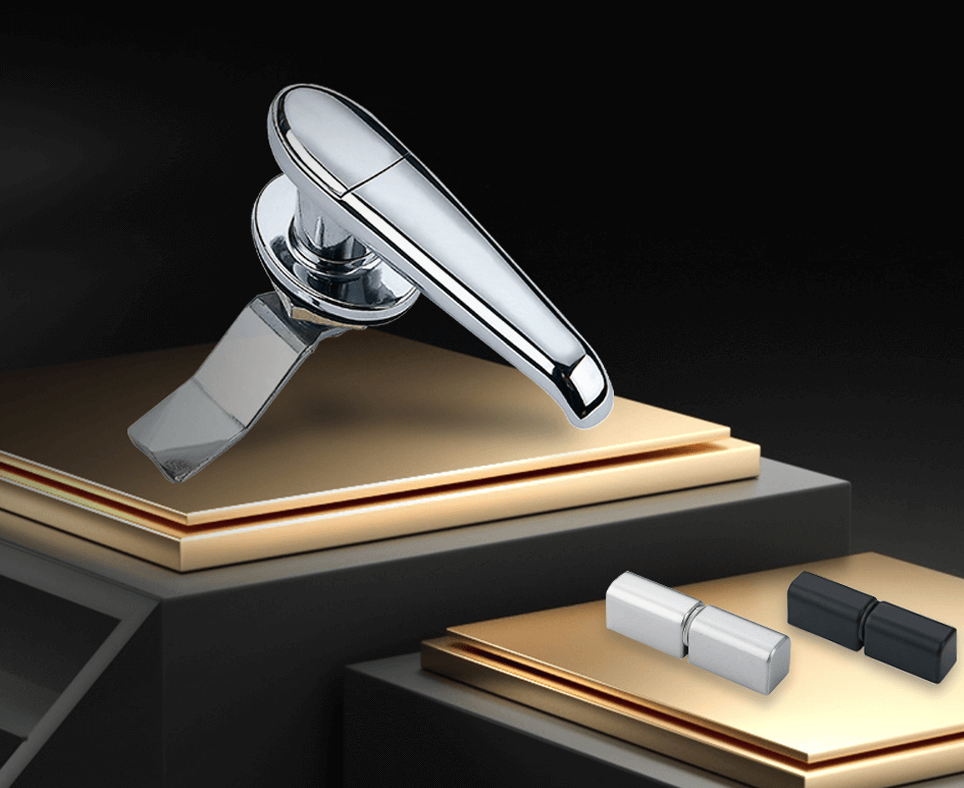

For easy opening, handle locks are your ideal solution. Not only are they convenient and feature-packed, but they’re ideal for construction machinery as well.

These locks are incredibly easy to open, and anyone with basic tools can do it. All that needs to be done is insert either a flathead screwdriver or the end of a small Allen wrench into the hole and push down on a metallic detent pin.

These are the most prevalent type of door locks and can be found on residential and commercial doors alike. Unfortunately, they’re less secure than deadbolts, so when security is key, use them in conjunction with them for maximum protection.

Handle locks are cost-effective, making them a great option for homeowners seeking both durability and security. Unfortunately, they lack all of the safety features of deadbolts, so you should inspect them thoroughly to confirm they meet all your security requirements.

Are you searching for a secure way to keep your construction machinery safe? Chances are you’ve encountered the lock and handle combination. Not only does this provide effective security for your equipment, but it can add some aesthetic appeal to the building or site as well.

When selecting a lock, it’s essential to know which type is most suitable for your requirements. Lever latches, knobs, and padlocks all have advantages and drawbacks; thus, selecting the right one for your requirements is key.

Though knob locks may not be the most secure type of lock, they still provide effective security and make an excellent addition to any home. Plus, installing and adjusting them is simple; just be sure to do it correctly and not overtighten screws, as this could cause the mechanism to bind up. For optimal results, clear out the cylinder of any debris blocking it, so the mechanism runs smoothly and functions optimally – saving time and money in the long run!

If your home or business requires replacing a door, handle locks are an ideal solution. They’re simple to install and will make your job much simpler. Plus, these come in various colors and styles so that they suit any taste or preference.

To begin, take off the existing lock and handle from your door. You may need to give it a little tug in order to loosen the hardware, but once lost, you should have no trouble pulling them apart.

Next, mark the holes for your new handle and lock. Doing this ensures they are drilled in the proper places, so you don’t have to spend extra time trying to re-drill later on.

Installing and maintaining handle locks is a snap, making them both simple to install and care for. To keep your hardware in prime condition, regularly cleaning both locks and handles is important; using a damp cloth with mild soap works best; alternatively, you may lubricate your hardware to extend its lifespan.

It is essential to use quality lubricant on all hardware. Not only will this protect the hardware from rust, corrosion, and other damage, but it also reduces friction in the locking mechanism – essential for locks that can withstand considerable pressure yet still function smoothly.

Handle locks are a breeze to install and maintain compared to other lock mechanisms, thanks to materials like stainless steel, copper, and aluminum that offer strength and reliability.

To guarantee the durability of handles and lock mechanisms, manufacturers apply protective coatings to their metal surfaces. These coatings are anti-corrosives and give locks a polished, modern appearance.

Once coated, metals are tested for adhesion and resistance to salt spray and moisture. Furthermore, they undergo a series of quality and security evaluations.

When installing a handle lock, it is essential to follow the manufacturer’s instructions closely. Otherwise, you could end up with an improper installation.

Some handle designs require the spindle halves to be inserted first before the latching mechanism is placed inside the door’s edge. If this applies to you, place a plastic washer around each spindle half before sliding the handle on.

Once all parts are installed, test them to confirm they work properly. If any issues arise, contact the manufacturer for assistance.

It is beneficial to lubricate your locks from time to time. Doing so reduces friction in the keyway of the lock and keeps it functioning smoothly. Apply a silicone-based lubricant or graphite powder; however, be careful not to use oil-based lubricants, which could attract dirt particles and cause your lock to malfunction.

Construction equipment requires regular upkeep to maximize its service life. Checking for signs of wear and tear on belts, batteries, and body parts should be part of any maintenance checklist.

One way to extend the life of your equipment is to lubricate it regularly. This reduces friction and slows down wear and tear on machinery. Use a dry powder lubricant such as graphite powder or Teflon; avoid oil-based products which attract dirt and make equipment more vulnerable.

In addition to lubrication, it is also essential to keep the lock clean in order to avoid sticking. This can be accomplished with simple routine upkeep and doesn’t necessitate any special tools.

It is recommended that you lubricate your locks at least twice annually. This can be accomplished by spraying dry powder lubricant into the keyway of your lock and turning them several times to distribute it throughout. Doing this helps keep pins and springs from sticking or becoming jammed, which in turn causes malfunctioning of the lock mechanism.

Handle locks are ideal for construction machinery due to their ease of upkeep and security. Plus, they’re affordable and simple to install – coming in various sizes and styles, so you can find one that meets all your requirements.

The ZONZEN is the pinnacle of security. Its sturdy, well-made design will solve all your rental security concerns. But its true star is its patented keyless entry system with a user-friendly interface. ZONZEN stands out from its competition despite a name that suggests they specialize in locks for military applications. Their portfolio of award-winning products is perfect for any commercial or residential property owner, regardless of size or shape.

ZONZEN offers a variety of smart home, energy management, and lighting control solutions in addition to the usual suspects. What sets this company apart is they truly listen to its customers; they have an attentive customer service team ready for any queries or problems you may encounter.

Our Customer service is unsurpassed. We have well trained customer service representatives that are ready to help you with your next project be it large or small.

Our R&D team keeps developing new items for customers all over the world to ensure that we keep the flow of new hot selling point. If you have any questions or suggestions, please do not hesitate to contact us for further assistance.